Long before anyone worried about volatile organic compounds in paint fumes or safe cleaning chemicals, chemists started tinkering with mixing propylene oxide and methanol. That’s how propylene glycol monomethyl ether—often tagged as PGME or 1-methoxy-2-propanol—was first born in the early 20th century. This clear, low-odor liquid gradually edged out harsher solvents in paints, inks, and cleaners during the 1970s, when folks started noticing the headaches and breathing problems linked to old-school chemicals. Factories and labs saw real potential in PGME’s ability to dissolve tough stuff without packing the same fumes or fire hazards. Much of its climb traces back to strict safety laws and advances in petrochemical reactions. Workers grew familiar with drums marked PGME as the push for greener, less explosive solvents reshaped chemical production lines from Europe to Asia.

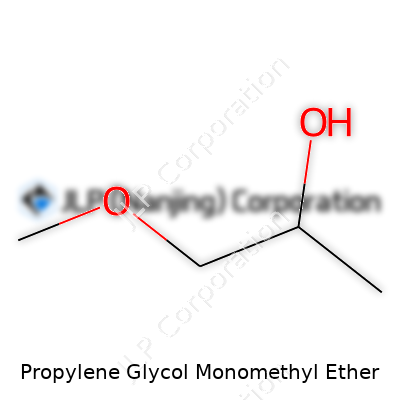

Walk into almost any plant churning out paints or inks and you’ll spot containers labeled PGME. Chemically, it’s an ether that swaps one hydrogen for a methyl group, pulling it out of the crowd of cheaper alcohol-based solvents. This tweak gives it enough power to dissolve greases and pigments, but spares you the choking vapor cloud that comes with older substitutes like toluene. A mixer can pour PGME into water or oil-based recipes without juggling long lists of additives; it bridges the gap, making sure sticky glues or quick-drying shellacs go on smooth and wash out in warm water. PGME rarely steals the spotlight, but behind almost every quick-drying paint or graffiti remover, it keeps systems running.

Take a whiff of PGME straight from the drum and you might notice the faint aroma, but unlike many ethers, it doesn’t floor you with fumes. The liquid doesn't freeze in a typical warehouse, and it boils just above the temperature of hot coffee—about 120°C. Workers find it keeps steady even as temperatures swing, so no need to jack up the air conditioning to protect the stock. Its molecular shape lets it play well with both greasy and watery messes, winning it fans in surface-cleaner formulas. PGME doesn’t flash into flames at room temperature, giving plant managers one less thing to worry about. Its vapor pressure sits low enough to avoid quick evaporation, which matters most if you’re tired of goo turning crusty on your paint tray. In short: it checks off many boxes most industries care about—stability, moderate volatility, and decent compatibility with other chemicals.

Producers pin down purity with GC-MS tests, usually certifying at least 99% concentration for industry use. You’ll see PGME labeled under its CAS registry number (107-98-2), the UN code for safe transport, and the standard hazard pictograms: “Flammable,” “Irritant.” Labels flag the need for gloves and goggles, which every seasoned hand in the mixing room already knows. Any decent drum of PGME comes stamped with batch numbers, country of origin, and test results for water content and acidity. These details save headaches in case customers complain about fishy-smelling paint or foggy windows after a wash. Audits and checks matter: fake or off-spec chemical lots cost too much time and money to ignore.

PGME owes its origins to a reaction between propylene oxide and methanol—two staples in the chemical world. A company will feed both into a reactor under controlled temperatures and pressures, using a metal catalyst to speed things along. Operators then distill the concoction, pulling off water and leftover bits until only PGME remains. It’s not glamorous work, but mistakes cost real money: excess methanol drops purity and leaves behind a harsh smell, while sloppy distillation turns out product that won’t pass a single QC test. Once finished, the solvent heads off to filler lines, where it lands in drums, totes, or bulk tankers.

PGME acts as a willing participant in a grab bag of chemical reactions. Labs often use it as a starting point, swapping out its methoxy group for more exotic attachments. For industrial tweaks, PGME can undergo etherification, turning it into PGME acetate, a solvent that dries even more slowly and suits specialty coatings. It also participates in reactions with acids and oxidizers—pretty standard for a glycol ether—though careful storage keeps undesirable changes at bay. Tweaking PGME’s structure lets research scientists nudge its odor, drying rate, and compatibility toward precise goals, adding value to fields like electronics and pharmaceuticals.

Chemicals rarely show up under just one name. Factories, shippers, and scientists bounce around alternate monikers such as 1-methoxy-2-propanol, propylene glycol methyl ether, PGME, and even trade names like Dow’s “Dowanol PM” or BASF’s “PM Solvent.” Read the fine print: safety sheets might use the IUPAC name or a brand synonym, and nobody wants to mix up PGME with similar-sounding solvents like ethylene glycol monomethyl ether, which triggers tougher safety rules. Clear communication clears up confusion—especially when international buyers order by catalog.

Every industry veteran treats PGME with a dose of common sense. Spills can irritate skin and eyes, and concentrated vapor causes dizziness or headaches, especially in tight spaces. Most countries cap workplace exposure at about 100 parts per million, and plants fit mixing boilers with fresh-air vents and spark-free pumps. Importers eye flashpoint and toxicity numbers to stay clear of shipping headaches or regulatory fines. Plant floors display big, bold placards: no open flames, no food in storage zones, prompt cleanups for splashes. Training beats accidents, and no operator skips gloves or goggles when handling open vats of the stuff.

PGME covers a lot of ground. Paint manufacturers rely on it for smooth flow in latex-based walls paints, while ink makers want the fast drying and clean-up. Cleaners lean on its ability to cut through greasy residues—meaning less elbow grease or harsh acids. Electronics manufacturers dip circuit boards in PGME-based degreasers to strip off oil without damaging tiny parts. Even the automotive world found a spot for it in glass cleaners and brake fluids. Office workers see the benefits every time they wipe a stubborn smudge from a computer screen or painted surface with a “no-streak” wipe. Despite fierce competition from newer solvents, PGME has a stubborn way of hanging on whenever performance, cost, and safety all matter.

Over the past decade, money poured into greener ways of making and using PGME. Some research labs dig into bio-based feedstocks, hoping to shake free from fossil fuel supply chains. Chemists also tinker with custom blends aimed at slashing workplace exposure or boosting recyclability. University teams focus on tracking low-level emissions inside buildings, as buyers grow fussier about “green” certifications on paint cans. Environmental watchdogs push for more public sharing of long-term health studies. All this poking and prodding makes open collaboration between labs, suppliers, and regulators much more common than in the past, even as competition between chemical giants gets ferocious.

Plenty of ink has spilled over PGME’s safety record. At low doses, lab rats occasionally show liver or kidney changes, though these results don’t always transmit directly to humans. Workers exposed in big manufacturing plants report fewer complaints than neighbors handling toluene or xylene, but persistent exposure can lead to headaches or mild skin rashes. Medical journals call PGME “relatively safe” compared to many organic solvents, but that word “relative” does a lot of work. Testing in pregnant animals points to possible impacts on offspring at cranked-up exposure levels, which kept certain uses in check. Whether you’re at a paint plant or a small print shop, proper use and regular checks seem to tip the scale toward safe handling. Doctors and regulatory scientists continue to scan for missed problems, relying on regular health surveys to fill the knowledge gaps.

As pressure builds for cleaner and safer chemicals, PGME stands at a crossroads. Hybrid paints and coatings demand solvents that play well with ever-tougher environmental rules—but keep the same price as before. Chemical engineers chase new synthesis routes that make PGME out of plant waste and cut greenhouse gases, aiming for bragging rights and regulatory headroom. Digital sensors and closed-loop systems could let plants slash airborne emissions and recycle solvents almost endlessly. The push for automation in chemical mixing floors calls for easier controls, so product purity stays high without extra labor costs. PGME’s long track record and reliability may secure its place, but only by staying flexible in the face of green chemistry demands, stricter rules, and a crop of new solvents gunning for a piece of the action.

Think about what you use to clean your windows, what painters choose for cutting through sticky residues, and even some of the things used in auto care garages. The same clear liquid shapes these experiences: propylene glycol monomethyl ether, or PGME if you prefer a mouthful in chemical talk. Few realize how often this stuff pops up in places outside the chemical plant. From my own work cleaning up old paint and sticky messes in a former job at a hardware store, I learned right away you can't dismiss the value of a powerful, fast-working liquid like this.

PGME shows up wherever someone needs something dissolved quickly without leaving ugly marks. In the back room at the hardware store, painters would trade tips on which solvent cuts through dried paint fastest. They swore by products loaded with propylene glycol monomethyl ether. Besides helping paint go on smooth, it pulls its weight in inks too. Printing shops mix it into their ink blends; thin lines look crisper, and smears become less common.

Take a trip through a supermarket's cleaning aisle and you'll spot it on labels for glass cleaners, degreasers, and polish sprays. The reason: it's tough enough to break down grease and grime, but it leaves surfaces streak-free. It works so well because of its ability to mix with both water and oil-based substances, something not every solvent can claim. This mixability gives companies flexibility. It also means fewer streaks on your windows or mirrors and a quicker cleanup after DIY projects.

Factories, garages, and workshops still put PGME to work in big batches. Mechanics lean on it for degreasing parts. Electronics assemblers depend on it to remove soldering flux. In these places, safety gear becomes just as critical as the product itself. Exposure over time raises concerns about skin or lung irritation. I've seen glove debates in break rooms; folks who go without often regret days of red, cracked hands. Factories need good ventilation and clear safety rules if they're using solvents like PGME.

PGME isn’t something you'd want spilling onto your skin for long, but so far, regulators haven't called for a ban. Countries like the United States and those in the European Union set exposure limits. They want workers safe, but also want to keep open the doors for industries that rely on this solvent.

The real question: How do we keep benefiting from something so useful while limiting the risks to workers? Some places invest in closed-system equipment, keeping vapors away from faces and hands. Others look into alternatives that don't irritate skin or lungs but still clean or dissolve just as well. Innovators try to tweak existing chemicals for lower hazard ratings, but many customers stick to what works unless laws push them elsewhere.

People keep looking for safer, greener ways to handle the messes and projects of everyday life. Yet even with buzz about sustainable chemistry, affordable and efficient substitutes don't grow on trees. Every year brings new research and testing; the challenge to match the effectiveness and versatility of a solvent like propylene glycol monomethyl ether remains tough. Change takes persistence and smart investment, especially for giant companies with tight margins. Until then, most folks in industries, from printing to auto repair, keep a close eye on their gloves and masks—and keep a can of their favorite solvent on a nearby shelf.

Many folks would be surprised how often propylene glycol monomethyl ether, or PGME, pops up in their lives. It's in paints, cleaners, inks, and even some beauty products. As someone who once spent hours in a cramped apartment painting the walls, I remember the headache that crept up on me, even with the windows wide open. Later, I learned that headache sometimes signals exposure to chemicals like PGME.

The chemical isn’t some distant threat in a factory somewhere — it’s right under our noses, literally. Workers who clean printing presses, painters, and those who spend time around industrial coatings get the biggest whiff. According to the U.S. National Institute for Occupational Safety and Health (NIOSH), breathing in high concentrations irritates eyes and noses, and people sometimes feel dizzy, tired, or nauseous. Splashes on the skin aren’t harmless either. Redness, dryness, and a tingly sensitivity can show up pretty quick.

Some people shrug off warnings, believing that everyday exposure stays far below danger levels. But the numbers matter. In labs, animals show signs of kidney and liver trouble after repeated exposure, and pregnant rats breathed in enough to see their babies affected. While humans don't face the exact same risks, the evidence shouldn't be ignored. The European Chemicals Agency lists PGME as a substance for which safe use demands care, especially in workplace settings.

Chemicals like PGME stick around because they’re useful and legal. Most laws lag behind the science, and guidelines leave employers and consumers to make their own calls. Just because a product sits on a store shelf doesn’t make it risk-free. Plenty of household products smell “clean” but contain harsh solvents. Anyone who’s scrubbed floors with a strong-smelling cleaner and coughed for hours afterwards gets a taste of this reality.

No one needs fearmongering. Small amounts from occasional use likely won’t wreck anyone’s health. But people with asthma, chronic headaches, or sensitive skin live with real consequences. If a paint or cleaning job leaves you coughing or dizzy, you remember the next time. I learned to check labels and wear gloves after realizing a simple pair cost less than a doctor visit.

Manufacturers have alternatives, and the demand for less hazardous solvents is growing. Some companies offer cleaner, water-based products. Shoppers can look for warnings on labels or dig into safety data sheets online. If you work in cleaning, painting, or printing, a mask, open windows, or better ventilation keep the chemical away from your lungs. Unions and workers can push for better protections, because shortcuts in safety pile up over time.

At home, ditching old habits helps. Swap out harsh solvents for gentler ones where possible. Reading the fine print on a bottle prepares you for what’s inside. If a project fills the air with strong fumes, give it space and time to clear. It’s not about panic. Knowledge puts people back in control of their own spaces and bodies.

People may not notice every threat hiding in a spray bottle or paint can, but paying attention makes a real difference over the years. PGME isn’t some evil villain, but it isn’t as innocent as a whiff of fresh paint, either. The more we know, the safer choices we can make, for ourselves and for everyone sharing the air around us.

Propylene Glycol Monomethyl Ether (PGME) doesn’t make the headlines much outside of industrial circles, but its storage isn’t something to brush aside. I’ve spent time in factories and chemical plants where getting the handling right spells the difference between business as usual and a row of safety alarms. PGME likes to stay out of trouble, so folks who work with it need to pay attention to a few hard lessons folks in the industry keep learning over and over.

PGME brings with it a strong odor and can irritate the nose and eyes in confined spaces. I remember one shift where a leaky drum in an unventilated corner sent a few people looking for fresh air and eye wash stations. Store this solvent in tightly sealed containers—think steel or high-grade plastic drums—kept in cool, dry places away from the sun. Flammable vapors hang around because it has a fairly low flash point (roughly 31°C or 88°F). Sparking tools or even static can turn a regular day into a disaster, so keep sources of ignition far from storage areas.

More than once I’ve seen the mess that comes with poor labeling. Unmarked drums get shuffled between warehouses; later, someone ends up mixing PGME with something it shouldn’t touch. Flammable liquid labels and proper chemical identification reduce mistakes, especially when the regular crew is out and temps fill the gap. Some shops post Safety Data Sheets right above the drums, just in case someone new needs a quick refresher on what they’re dealing with.

Moisture tends to mess things up more than you’d think. I’ve seen drums stacked outside slowly corrode, letting humidity sneak inside and spoil the product. Ventilation stops those chemical fumes from building up. Think exhaust fans, open windows, or even a simple fan nearby. Small investments like these stop headaches and eye irritation, not to mention sneezing fits.

A warehouse isn’t a chemical buffet. I once saw PGME stored next to snacks in a makeshift break room—bad call. Food contamination is real, and a mistake here reaches beyond workplace safety into public health. Avoid stacking PGME near strong oxidizing materials, such as peroxides or chlorates. When these mix, the outcome ranges from ruined products to dangerous reactions nobody wants to clean up.

Chemical leaks will happen if enough time passes. Spills soak into the concrete and, on hot days, vapors fill the air fast. Absorbent pads, sand, and proper waste drums save time and frustration. Staff should always have gloves and goggles nearby, often within arm’s reach, because it only takes one distraction to get a solvent splash.

No fancy safety system beats hands-on experience. Everyone on deck, from drivers to supervisors, benefits from basic training. Walk through the steps, practice the cleanups, and watch out for each other on every shift. Conversations around storage and handling last a lot longer than flashy warning signs, and they stick well after the new paint smell fades.

Anyone who’s ever spent a few hours stripping paint or cleaning electronics probably brushed shoulders with solvents they didn’t even notice. Among the lesser-known, yet widespread ingredients, sits propylene glycol monomethyl ether, often abbreviated as PGM or PGME. Its name doesn’t sound consumer-friendly, but you can find it behind the scenes in cleaners, inks, coatings, even some personal care products. The question keeps coming up around labs and plant floors: does it really mix with water, or does it separate out like oil?

I remember my first chemistry class, smelling faint traces of sharp, clean liquid during a solvent test. That time, discovering which chemicals play nice with water felt like unlocking secrets. PGME, with its structure combining a glycol backbone and a methyl ether tail, acts as a middleman. It links up with both water and oils. Unlike substances that form layers or cloudy emulsions, PGME dives in and vanishes. The two combine clear, with no trace of separation.

Industry handbooks and product safety sheets place PGME firmly in the water-miscible camp. That’s not a small detail. Water-miscible means it makes a truly uniform solution, not just a temporary blend that breaks apart with time. This feature allows companies to create products that clean, dissolve, and coat more evenly, without fighting those annoying streaks or residue.

Over years of working with cleaning fluids and paints, I’ve come to appreciate chemicals that actually rinse away without drama. Many older solvents, especially those based in petroleum or chlorine, leave behind slick films or irritate the skin. They’re a pain to dispose of safely. PGME offers a kind of reliability. Since it disperses so well in water, users can dilute leftovers and sweep up residues with less waste and fewer hazardous byproducts.

The environmental stakes can’t be overlooked. Solvents that don’t mix with water stick around, seeping into soil and water tables. PGME breaks that pattern. Because it mixes fully, on-site treatments—like water purification and chemical neutralization—become easier and cheaper. Less toxic runoff means fewer headaches for local water departments. That’s the sort of thing local governments appreciate, especially as regulations around wastewater keep tightening.

PGME isn’t without issues. Even with its friendly chemistry, inhaling large amounts can cause headaches or dizziness. Overexposure sometimes brings mild irritation. Safety data stresses good ventilation. In labs I’ve worked in, sinks and eye washes sit close by for a reason. Even substances that dissolve completely in water deserve respect. Gloves, goggles, and proper storage aren’t negotiable.

Safer chemicals, including those based on green chemistry, have started to nudge into the scene. Some use bio-based ingredients instead of traditional glycols. These don’t always have the same performance as PGME, though. The push to find something even less toxic and more biodegradable grows each year, but so far, PGME still holds a role thanks to its effectiveness and low volatility.

For professionals mixing batches, filling tanks, or cleaning machinery, knowing a solvent’s behavior in water shapes every step. With PGME, workers get a reliable partner that fits a range of tasks without complex handling. That means faster cleanups, less chance of harmful exposure, and a bit more peace of mind around the shop or factory floor. Keeping this balance of performance and safety in mind leads to smarter decisions throughout industry.

Walk through any city’s industrial district, and you’ll see crews rolling fresh paint onto bridges or workers cleaning grime from factory machinery. A common thread in both cases is the presence of propylene glycol monomethyl ether, often just called PM. This solvent works hard behind the scenes, blending well with water and helping break down stubborn greases and resins. Like folks expect their paint to stay smooth on a rainy day or their cleaning sprays to strip away tough marks, PM delivers by keeping both paint and cleaning mixes from separating and drying too fast or too slow.

Paint makers reach for this solvent while mixing up cans of acrylic and latex coatings. PM does more than just keep everything mixed—it helps the color spread out evenly, and keeps the brushstrokes from getting sticky or rough before the crew has finished a wall. As someone who’s spilled their share of paint and sweated through hours of scraping off poorly-applied finishes, I can’t overstate the value in a product that gives you just a bit more time to get it right.

Flip open almost any modern device and you’ll see the tight circuit patterns and delicate plastic layers. Getting these parts clean during manufacturing takes more than just soap and water. PM steps up here too, showing up in degreasing baths and specialty wipes. Because it doesn’t easily chew through plastics or leave a sticky coating, electronics makers trust it for jobs where both safety and purity matter. I remember talking to factory techs who joked that finding the right cleaner felt like balancing on a wire—use the wrong chemical and a batch of chips could short out or corrode long before it hits a store shelf.

Printers and packaging factories face a daily challenge with ink. The mix has to flow just right, dry at the right speed, and leave sharp lines without smudging, whether it’s newspapers or food labels. PM enters the process to help with exactly these points. It keeps the ink from drying out in the rollers, helps stop clogs and blots, and allows for high-speed runs that modern factories depend on. I’ve seen workers curse jams and smears on massive presses, where the wrong solvent means hours lost and piles of paper wasted. The push toward sharper packaging and detailed labels in grocery stores relies partly on what PM brings to the ink game.

Repair shops and maintenance crews need something stronger than water, but less harsh than many industrial solvents. PM lands in the sweet spot for many of these jobs—removing grease, stripping off old varnish, prepping surfaces for new coatings. Large engine parts come caked with oil and carbon, and PM-based cleaning mixes help get these back to working order without pitting the metal or leaving residues that reduce performance. I’ve watched team leads swear by a PM-based cleaner after years of trial and error with harsher chemicals that would sometimes eat away at gaskets or sensitive parts.

Across industries, there’s plenty of talk about worker safety and reducing harsh chemical exposure. PM wins points here—it tends to evaporate slower than old-school solvents like acetone, and gives off less sharp fumes. Factories and workshops have embraced it as an aid to workplace comfort and regulatory safety limits. That means fewer breathing complaints and less risk of headache or dizziness during long shifts. Still, keeping up on ventilation, training, and personal protection remains crucial. No solvent, even those with a gentler reputation, comes without its own handling rules.

Companies that want cleaner processes and safer products now look at PM as a useful compromise. They can cut back on toxic ingredients and still keep their workflow humming. If the industry finds greener alternatives with the same benefits, workers and the environment would both come out ahead. For now, though, PM isn’t just a technical additive—it’s a tool that shapes how things look, work, and last in the world around us.

| Names | |

| Preferred IUPAC name | 1-Methoxypropan-2-ol |

| Other names |

1-Methoxy-2-propanol PGME Propylene glycol methyl ether Methoxypropanol Dowanol PM |

| Pronunciation | /ˈproʊ.piː.liːn ˈɡlaɪ.kɒl ˌmɒn.oʊˈmɛθ.ɪl ˈiː.θər/ |

| Identifiers | |

| CAS Number | 107-98-2 |

| Beilstein Reference | 1209288 |

| ChEBI | CHEBI:8185 |

| ChEMBL | CHEMBL1717233 |

| ChemSpider | 6751 |

| DrugBank | DB02000 |

| ECHA InfoCard | 100.021.240 |

| EC Number | 603-064-00-3 |

| Gmelin Reference | 1080 |

| KEGG | C02331 |

| MeSH | D026526 |

| PubChem CID | 7955 |

| RTECS number | UU2000000 |

| UNII | 6H3KQ33UFA |

| UN number | UN3092 |

| Properties | |

| Chemical formula | C4H10O2 |

| Molar mass | 90.12 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Mild ether-like |

| Density | 0.921 g/cm3 |

| Solubility in water | Miscible |

| log P | “-0.44” |

| Vapor pressure | 1.67 mmHg (20°C) |

| Acidity (pKa) | 14.8 |

| Basicity (pKb) | 15.1 |

| Magnetic susceptibility (χ) | -9.7×10⁻⁶ |

| Refractive index (nD) | 1.404 |

| Viscosity | Viscosity: 1.7 mPa·s at 25°C |

| Dipole moment | 3.75 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 178.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -477.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2920 kJ/mol |

| Pharmacology | |

| ATC code | D02AX10 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P271, P280, P303+P361+P353, P304+P340, P305+P351+P338, P312, P337+P313, P370+P378, P403+P235, P501 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 42 °C |

| Autoignition temperature | 287 °C (549 °F) |

| Explosive limits | 1.5% - 13.1% |

| Lethal dose or concentration | LD50 (oral, rat): 5660 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 4,016 mg/kg |

| NIOSH | RN 107-98-2 |

| PEL (Permissible) | 100 ppm |

| REL (Recommended) | 100 ppm |

| IDLH (Immediate danger) | 1500 ppm |

| Related compounds | |

| Related compounds |

Methyl Ethyl Ketone Propylene Glycol Monomethyl Ether Acetate Ethylene Glycol Monomethyl Ether Propylene Glycol Diethylene Glycol Monomethyl Ether |