Back in the late 1600s, curious scientists puzzled over why ants produced such a biting sting. John Ray isolated the pungent liquid from crushed ant bodies, giving the world its first real glimpse at what he named “formic acid,” after the Latin word for ant. This substance later showed up in the chemistry labs of Europe through distillation and other extraction tricks from all sorts of natural matter. Chemists eventually ditched ant collection methods as better synthetic approaches rolled out, especially as the dye and leather industries grew hungry for new and stronger acids. Through the Industrial Revolution and into the modern petrochemical landscape, people realized that formic acid wasn’t just a curiosity from insects; it had the chops to play in big industry.

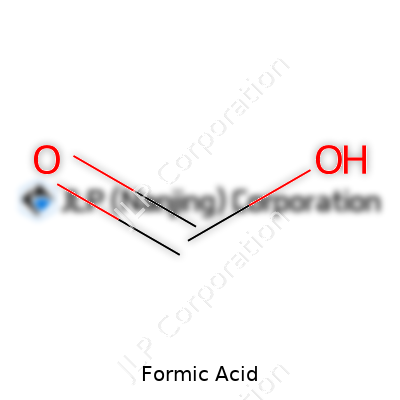

Formic acid shows up in the real world as a colorless liquid with a strong, penetrating smell. Its simple molecular structure, CH₂O₂, packs a surprising punch, reacting quickly in many settings. Unlike weaker acids, formic acid breaks down easily with heat and air but refuses to linger, leaving almost no residue. Buyers find it bottled up—or packed in tanks—at concentrations usually ranging from 85% to nearly pure, with a water-clear appearance and a whiff that reminds you what strong chemistry smells like. You can spot its name on technical datasheets across agriculture, rubber production, and leather processing. Sometimes it's called methanoic acid, but—unless chemistry is involved—folks just stick with "formic acid."

Formic acid doesn’t freeze in an average winter—melting at just above 8°C (about 46°F)—and it boils at around 101°C (close to 214°F), hovering right at the edge of water’s boiling point. The acid dissolves well with water, ethanol, acetone, and even ether. What’s interesting is how it behaves both as an acid and a reducing agent. This dual personality means formic acid reacts in more settings than just your standard acid—sometimes it donates a proton, sometimes it hands over electrons. It can break down into carbon monoxide and water with the right combination of heat and strong acids, and it reacts rapidly with alkalis, metals, and organic compounds. Left on a shelf, it can start corroding metals and plastics that aren’t up for the job.

Suppliers package formic acid in varying grades. Technical grade often lands at about 85% concentration, aimed at industry, while analytical or pure grades push above 98%. Every container must highlight signal words (“Danger—Corrosive!”), CAS numbers, hazard pictograms, batch numbers, and concentration. In my own work, getting the right label meant the difference between manageable risk and an hour with the hazmat crew. Regulations from the UN and local governments demand containers withstand corrosion and carry clear labeling to avoid confusion. Leak-proof packaging and venting help prevent accidental pressure buildup from decomposition.

Nobody crushes ants these days. Chemical plants usually derive formic acid out of carbon monoxide and sodium hydroxide, which gives sodium formate—then acidified to release the acid. Some facilities create it as a sideline product during acetic acid production, or break down methanol with carbon monoxide under acid catalysis. Old textbooks talk about fermentation of sugars with special bacteria, but that route stays mostly in the lab or research. In practice, the CO and NaOH route offers scale, reliability, and a level of safety that keeps workers out of danger’s way.

Formic acid isn’t shy about joining in chemical reactions. The classic move—acting as a reducing agent—lets it clean up metal oxides or even break down nitro compounds to amines. This ability to donate hydrogen helps convert carbonyls in organic synthesis and prevents rust in industrial boilers. Add strong acids, and formic acid decomposes, with bubbles of CO and scary-looking fumes. With alcohols, it can form esters, producing a fruity aroma used in flavoring and fragrance industries. Trying to store formic acid with reactive metals or strong bases? That’s a recipe for leaks, corrosion, and sleepless nights for safety managers.

Anyone digging into catalogs or research papers will spot formic acid listed as methanoic acid and less often as hydrogen carboxylic acid. Containers might bear tradenames like "Ensform," "Ameisensäure," or the old “ant acid” title. Some commercial blends use code numbers or abbreviations, but globally recognized naming standards default to “formic acid” and the ever-present “CAS 64-18-6.” Broader industrial catalogs highlight cross-listings to keep confusion at bay.

Handling formic acid has always required respect. Skin contact produces burns, and just a few breaths of vapors can irritate lungs and eyes. In plants I've visited, workers gear up in goggles, acid-resistant gloves, and sometimes full-face respirators. Emergency showers and eye wash stations don’t just collect dust—they provide insurance for the “what if” moments. Spills need to be diluted and neutralized with alkalis, while fire crews use dry powders or CO₂ since water jets spread corrosive runoff. Wastewater containing formic acid heads to neutralization tanks. Safety data sheets—always updated and nearby—save lives when spills or exposures happen. A culture of safety, with regular retraining and drills, cuts down the incident rate as much as any new PPE innovation.

Few chemicals punch above their weight like formic acid. Farmers use it in silage, preserving feed from spoilage and encouraging fermentation. Tanners and dyers rely on its acidity and low odor to soften hides and fix dyes. Rubber producers cure latex with it, splitting the colloids to create tough, finished products. In beekeeping, controlled vaporizations clear out parasitic mites. Some laboratories run formic acid in peptide synthesis, using its reducing power to protect delicate molecules. Cleaning agents harness its biting acidity for descaling kettles and boiler systems. Roads in cold climates see small amounts mixed with salts as a deicer. Each sector values formic acid for what it does simply—no frills, just straightforward reactivity.

In recent years, research has hit new heights tackling how to make formic acid more sustainably. Biochemical engineers chase routes that turn crop waste or even captured CO₂ into valuable acid with enzymes or specialized bacteria. Bench chemists experiment with catalyst tweaks to improve selectivity and cut down on dangerous waste. Electrochemical engineers use renewable electricity to power CO₂ reduction reactions, pitching it as a green alternative for the energy sector. Scientists dig for pathways that unlock new materials—polymers, pharmaceuticals, cleaner pre-treatments—all while managing formic acid’s corrosive nature with upgraded handling tech. Research funding increasingly goes toward both greener manufacturing routes and new application fields in energy storage.

Toxicologists learned early that formic acid causes tissue damage on contact. Rats and other test subjects exposed to vapor showed rapid respiratory distress, while workers in manufacturing developed rashes and eye irritation without proper protection. Chronic exposure, particularly through inhalation or unwashed skin contact, can escalate to kidney or nerve damage. Toxicology studies usually pinpoint low doses as minimally harmful, with the big risk lurking in spills, splashes, or poorly ventilated spaces. Governments have set occupational exposure limits, and regular air monitoring keeps factories safer than they used to be. Veterinary and environmental testing make sure agricultural run-off stays within thresholds that protect wildlife.

Industries continue to look for ways to expand formic acid’s reach. With pressure to decarbonize, researchers see it as a promising chemical for hydrogen storage—thanks to its ability to act as a liquid hydrogen carrier. Its use in biodegradable plastics and as a raw material for next-gen batteries garners more attention every year. Green chemistry approaches, swapping fossil fuel feedstocks for bio-based sources, now look achievable as catalysts and process controls improve. With climate change and resource scarcity cutting into the status quo, formic acid’s versatility and reactivity could turn it from a background performer into a cornerstone for future manufacturing and sustainable energy systems.

Formic acid may sound like it belongs only in a chemistry textbook, but it shows up in places regular folks wouldn’t expect. Most people know it as the chemical in ant stings, giving those bites that unpleasant, stinging burn. Nature figured out this little acid long before factories got their hands on it.

What stands out for me is just how much farming leans on formic acid. Farmers mix it into silage – chopped up plants stored for cattle feed – to keep bugs and mold away. Silage will rot quick if left on its own, since moisture breeds bacteria. By tipping in a bit of formic acid, the feed stays fresh longer. That saves money and cuts waste, and it also means cows don’t end up sick from spoiled food.

In my own youth on the farm, the pungent, vinegar-like smell of silage told you formic acid was at work. We could tell from experience how feed treated with it lasted longer, especially in warm, wet summers when rot would be relentless. Without it, days of labor could vanish overnight.

Few people think of what goes into making leather boots or denim jeans. Tanneries use formic acid to clean animal hides, stripping away fat and hair, prepping them for dye. The acid helps open the fibers so color sticks better. Factories spinning out wool or cotton also put the acid to work; it adjusts the pH and softens the goods, making them easier to handle, softer to the touch.

Preservatives matter in big food factories. Formic acid keeps bacteria and molds from growing in livestock feed and even honeybee colonies. Beekeepers trust it to fight off mites that could wipe out whole hives. That makes formic acid crucial, since bee health ties back to the crops they pollinate, and by extension, to grocery store shelves everywhere.

Factories and car washes rely on strong but simple compounds. Formic acid helps remove rust and mineral buildup from metal parts. It works sharper and with less fuss than more hazardous chemicals. In winter, airport runways use deicers containing this acid, which tackles ice but doesn’t destroy the environment like other salts do. Chemical labs, too, count on formic acid for making solvents and household disinfectants.

Factories producing rubber need it for a quick curdle in the latex. Tire manufacturers, glove makers, and the folks making thousands of balloon animals all owe a nod to this acid. It pulls double-duty – cleaning and acting as a building block for more chemicals. The stuff’s hardly glamorous, but it makes things run.

It’s easy to forget that even a simple acid can cause trouble if misused. Direct exposure burns skin or eyes, and breathing it can be hazardous. Workers using it need gloves, masks, and smart handling rules. Regulators keep limits in place for how much turns up in food or water. Safer storage and spill plans in factories can cut risks. An accident on a big scale could threaten water supplies and farm fields, so safety matters as much as the benefits.

Formic acid plays a quiet but vital role in food, farming, cleaning, and manufacturing. Its usefulness comes down to careful, everyday choices – both on the line and on the land.

Formic acid shows up in all kinds of workplaces — from chemical labs and manufacturing to farms and pest control jobs. This chemical can pack a real punch. Spill a little on your hands and you feel it right away. Mistakes can mean chemical burns or breathing trouble, and that’s no scare tactic. After handling formic acid on a busy production line, I’ve come to respect its bite and the discipline it demands.

Folks sometimes shrug off gloves or goggles to save a minute or two. That shortcut can land you in the emergency room. I’ve seen what happens when skin meets formic acid—it feels like a wasp burn gone wild. Standard nitrile gloves work, but check for holes before you trust them. Face shields and safety goggles become your friends when splashes can come out of nowhere, especially if you’re pouring or mixing. Even your shop shirt should cover your arms. Those open sleeves might look cool but they let acid drip straight onto bare skin.

Fumes creep up before you know it, especially in small rooms or tight corners. At one plant, we pushed for a real exhaust hood over the work area — not just a cracked window. Moving the air out fast matters. Breathing in formic acid vapor leaves you with a burning nose and throat. More than once, someone ignored the warning signs and staggered outside with red eyes and a cough. Nobody wants that. If the air feels stuffy or bites at your sinuses, leave the room and check ventilation.

Leaving open containers of formic acid on the workbench is a rookie mistake. Always use tight lids and tougher plastic or glass. I once watched a cardboard box fall apart under a leaky bottle — we lost some good gear to that mess, and it didn’t smell great for days. Keep formic acid bottles below eye level. If something slips, you want it falling away from your face, not into it. Mark those bottles clearly so nobody grabs them by accident, especially if you share a workspace with others.

Eye wash stations and showers shouldn’t collect dust. If acid splashes on the skin or face, seconds count. One time, a coworker fumbled for the eyewash handle and lost precious moments. Make sure new folks know where everything is and how to use it. Don’t rely on memory during a real emergency — run drills if you need to. Even a half-minute exposure can mean permanent damage. Neutralizers and clean water need to be right at hand, not buried in a locked closet across the hall.

It’s easy to let routine take over, especially if you’ve handled strong chemicals for years. But every new person, and even the veterans, benefit from a clear run-down of safety steps. Walk folks through PPE, storage, spill cleanups, and emergency moves. Share real stories, not just textbook warnings — like the time someone ignored a tiny drip on their glove and ended up peeling skin off later that night. Nothing beats firsthand stories to drive home the risks.

People handling formic acid work smoother and safer when they watch each other’s backs. A quick heads-up about an open bottle or a ripped glove could save a hospital trip. Small talk in the lab or shop? Ask if they remembered to check their gear. Speak up early instead of fixing a problem later. Safety sticks better as a team habit than as a rule posted on the wall.

Formic acid is one of those chemicals that seems simple at first glance, but there's a catch. Before anyone tries using it—whether cleaning, preserving, treating leather, or experimenting in the lab—it's worth asking about the strength: what's the actual concentration? Too many folks skip over that question and wind up in trouble, either because their batch doesn’t perform, or because someone gets hurt.

Most formic acid offered to the market lands around 85%. This is strong stuff, enough to do real work in all the places formic acid gets used. But there's a noticeable difference if someone grabs a diluted bottle instead of a concentrated one. Let’s say you’re a beekeeper fighting off mites. Your bees count on you to use the proper mix. If the acid is watered down, pests might shrug it off. If it’s too strong, the bees and their keepers could get a sting of their own.

Food and feed businesses face serious scrutiny here. Residues matter, and a little miscalculation in formic acid concentration can spoil more than just a batch. Regulators don’t cut shops any slack if their labels do not match what’s on the invoice.

Anybody who's seen industrial grade formic acid knows it isn't always as pure as they'd hoped. Production brings in traces of methanol, heavy metals, and other chemicals. For most industrial use, that doesn’t make a difference. For laboratories, research, or pharmaceuticals, it turns into a headache. In college, I watched a test fail—and a week’s work go out the window—because the supplier didn’t flag the impurities. Since then, I ask for a certificate of analysis every time.

Plenty of people think purity is a detail only chemists should worry about. That’s not quite right. Low-purity formic acid can corrode metal tanks and pipelines in a factory faster than anyone expects. Sometimes, it even produces weird smells or side reactions in finished products. Farmers using the acid to preserve silage may lose feed quality if something is off. It’s not just about safety data sheets and red tape; it's cash on the line, and headaches for weeks afterward.

Trustworthy suppliers keep their paperwork in order and don’t try to hide details. They’ll gladly explain whether their jug contains 85%, 90%, or a special dilute blend. They’ll mention what else sneaks in alongside the acid. It’s smart to ask direct questions—don’t assume a label means clarity.

For personal or small-business users, a simple test with titration kits or consultation with a local chemical lab saves hassle. A bit of checking beats a lot of fixing down the road.

There’s still a need for plain talk about chemicals and their concentrations. It helps all users get the results they expect—and stay safe. Nobody likes surprises in a bottle, especially when formic acid is supposed to be doing something important.

Something as small as a mistake with storing formic acid can turn into a real mess. I remember the first time I worked near a chemical storage room, the air hit me with a sharp, sour smell. I later learned that was the faint whiff of formic acid, strongest near a loose cap. That smell alone tells you how quickly it escapes and how careful you have to be.

Formic acid might seem harmless at a glance—it shows up in nature, even ants make it. But it stings skin, burns eyes, and its fumes hit your lungs. Storing it in the wrong spot sets you up for accidents. A friend lost a pair of shoes because a container leaked—days later the floor had pale marks and the soles were gone. If it can do that to shoes, imagine what it does in a storage closet with weak lids or bad ventilation.

Forget thin plastics. Formic acid eats through most materials that aren't specifically built for the job. Stainless steel picks up corrosion quickly. Glass works, so do some HDPE plastics, but you won’t find me trusting just any jug from the hardware store. Manufacturers sell containers with tight-sealing lids made for acids like this. Those containers cost a bit more but stop leaks and spills from turning into emergencies. I've seen proper drum labels get faded by acid vapor—good containers and clear, permanent labels stay readable, which helps people know what’s inside even years later.

No one wants to store formic acid near heat or open flames. It boils at a lower temperature than water. In a warm room, pressure builds fast, lids pop, and acid sprays where you least expect. A cool, dry, well-ventilated room works best. I always look for ground-level storage, away from sunlight. Anything stacked above shoulder height is asking for spills, especially in rooms that get hot in summer.

Spills don’t happen every day, but it's smart to prepare. I’ve watched people scramble for water and towels—bad idea. Water can splash acid onto skin and eyes. Companies keep spill kits with neutralizers like soda ash or baking soda nearby. I keep a box under the workbench, right next to thick gloves and goggles. That way, if something leaks, it doesn’t take fifteen minutes to find the gear. You won’t stop every drop, but you can slow the damage.

I’ve sat through hours of safety meetings. Some folks would rather be anywhere else, but getting lazy gets you hurt. People need to know how acid fumes feel in your lungs, what goggles can actually save your vision, and why locking up the store room matters. Practicing what happens if a bottle tips over isn’t fun, but it builds habits that keep everyone safe.

Never store acids together with bases—one mix-up gets worse fast. I also double-bag my gloves, since formic acid eats right through thin latex. Cheaper bottles saved a few bucks once, but cleaning up after a cracked one costs more in the end. Invest in the right equipment, keep the storage area tidy, and check each container every week for cracks or swelling. A short walk-through on Monday morning prevents the kind of Monday you never want.

Cutting corners with formic acid leads to slips, ruined equipment, and sometimes, hospital trips. I’ve seen both carelessness and good habits up close. Only the careful ones go home with all their skin, shoes, and stories intact.

Folks use formic acid across agriculture, textiles, rubber processing, and even in fuel cells. It packs a punch in cleaning and animal feed, but not everything in the chemical toolkit likes to play nice with it. Grab a bottle without thinking about what’s in the drum next door, and you’re asking for trouble.

Formic acid is a pretty simple molecule. That simple structure makes it surprisingly feisty. Toss it in with something alkaline like sodium hydroxide, and you’ll get formate salts along with heat. Throw in bleach, and you risk creating toxic gases. It’s easy to see why chemical mishaps start in unventilated rooms or workshops where folks figure “sure, that’ll be fine.” It won’t.

A few years back, I helped a friend at a small tannery. The owner liked to save a dime by reusing plastic barrels. We noticed barrels that once held strong bases were cleaned with a weak rinse, then filled with formic acid for leather softening. You could see bubbling and discoloration. A local chemist warned us: “That’s not just dirt. That’s a reaction.” Little errors like that can send fumes through a factory or eat through plastic fast.

It’s not all about the dramatic chemical drama. Long-term storage matters, too. Formic acid gnaws at metals like iron, zinc, and aluminum. The process might not explode anything, but leaching metal ions into a solution can mess up water treatment, farming mixes, or fuel cell parts. Copper piping? Don’t even think about it. I remember testing water in a rural co-op after a few years of dosing cow feed with formic acid. The system slowly filled with rust particles – nobody saw it coming.

Certain plastics hold up well, including HDPE and PTFE. Go cheap with regular PVC piping, and you’ll find blisters and pinholes by next year. That turns a small leak into a full-blown contamination risk. If you run acid through equipment with dodgy seals or leftover mineral build-up, you expose yourself to both equipment failures and unsafe working conditions.

Anyone aiming to blend or store chemicals, whether for farming or cleaning, needs a habit of reading spec sheets and consulting compatibility charts. Some companies make laminated charts with lists of “yes” and “absolutely not”—if your job involves handling acids, that little chart is gold. Online, the CDC and NIOSH have plain-language guides. From experience, more folks take safety seriously once they’ve handled a spill and realized how fast formic acid seeps under doors or burns skin.

Routine checks on storage drums, mixing tanks, and pipelines save headaches—and money. Switching out susceptible materials for acid-resistant choices sometimes costs a little more up front, but repeat clean-ups cost more down the line.

If I see anyone prepping to mix or store unfamiliar chemicals, I remind them: chemistry is unforgiving to shortcuts. If you’re not sure about a material, ask someone who’s handled it before or look up compatibility resources. That habit, learned from years working around leaky tanks and stained workbenches, cuts down on panic and disaster more than any fancy lab gadget or safety slogan.

| Names | |

| Preferred IUPAC name | Methanoic acid |

| Other names |

Methanoic Acid Aminic acid Hydrogen carboxylic acid |

| Pronunciation | /ˈfɔːrmɪk ˈæsɪd/ |

| Identifiers | |

| CAS Number | 64-18-6 |

| Beilstein Reference | Beilstein Reference: 1209230 |

| ChEBI | CHEBI:28471 |

| ChEMBL | CHEMBL521 |

| ChemSpider | 266 |

| DrugBank | DB01942 |

| ECHA InfoCard | 01aee3c6-7186-4626-8b7a-b8c973b1e7f1 |

| EC Number | 200-579-1 |

| Gmelin Reference | **Gmelin Reference: 171** |

| KEGG | C00047 |

| MeSH | D006 Formic Acid |

| PubChem CID | 284 |

| RTECS number | LR0350000 |

| UNII | 9QH242BBR6 |

| UN number | UN1779 |

| Properties | |

| Chemical formula | HCOOH |

| Molar mass | 46.03 g/mol |

| Appearance | Clear, colourless liquid |

| Odor | Pungent, penetrating |

| Density | 1.22 g/cm³ |

| Solubility in water | Miscible |

| log P | -0.54 |

| Vapor pressure | 5.7 kPa (at 20 °C) |

| Acidity (pKa) | 3.75 |

| Basicity (pKb) | 10.33 |

| Magnetic susceptibility (χ) | −15.7×10⁻⁶ |

| Refractive index (nD) | 1.371 |

| Viscosity | 1.57 mPa·s (at 25°C) |

| Dipole moment | 1.41 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 129.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −425.0 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | −254.0 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | D08AX01 |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS05,GHS06 |

| Signal word | Danger |

| Hazard statements | H226, H314, H331 |

| Precautionary statements | P261, P280, P301+P330+P331, P303+P361+P353, P305+P351+P338, P310, P312, P363 |

| NFPA 704 (fire diamond) | 3-2-2酸 |

| Flash point | > 69°C |

| Autoignition temperature | 601°F (316°C) |

| Explosive limits | 12–18% |

| Lethal dose or concentration | LD50 oral rat 730 mg/kg |

| LD50 (median dose) | LD50 (median dose): 730 mg/kg (oral, rat) |

| NIOSH | MW4800000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Formic Acid: 5 ppm (9 mg/m³) |

| REL (Recommended) | 30 mg/m³ |

| IDLH (Immediate danger) | 30 ppm |

| Related compounds | |

| Related compounds |

Acetic acid Oxalic acid Methanol Formate Sodium formate Methyl formate Formamide Formyl fluoride |