People in labs started blending ethylene and vinyl acetate back in the 1950s. Researchers wanted something tougher than polyethylene but with a bit more flexibility and stickiness. Over time, manufacturers realized this blend could answer a lot of problems. Foam sheets for playgrounds, flexible packaging, and even artificial turf backing—all of these took shape once companies got serious about scaling up production. DuPont played a big role here, making EVA household knowledge in the plastics world. After the 1970s, as more industrial plants joined in, prices dropped and EVA became a staple in supply chains around the world.

Pick up a yoga mat, a hot melt glue stick, or even the cushioning in your running shoes—chances are, you’re holding ethylene vinyl acetate. The material looks like a plastic, acts like soft rubber when you want, and stands up pretty well to sunlight and rough handling. Shoe makers use foam blocks of it for soles because it takes shocks, doesn’t crack in cold air, and costs less than natural rubber. In packaging, sealing film made from EVA keeps food fresh and safe from air, which helps cut waste across the board.

EVA’s main calling cards: flexibility, resilience, and its see-through look. It feels soft, bends under pressure, and bounces back even after folding. Chemically, EVA resists water and most household chemicals, so it lasts through wash cycles and outdoor use. Its transparency makes it useful where you want to see what you’re wrapping or storing. EVA contains different amounts of vinyl acetate—more VA softens it up, less makes it firmer. Melting points stay between 85 and 160°C, depending on the ratio, so makers adjust recipes for the job at hand. I’ve seen handymen heat EVA sheets with nothing more than a heat gun to mold protective padding or case inserts on the job.

Manufacturers list vinyl acetate content in percentages—common grades range from 5% to 40% VA content. Material data sheets spell out density, melting point, tensile strength, and elongation at break. On the shop floor, labeling needs to match intended uses, like FDA approval for food contact, medical device ratings, or flame resistance for electrical parts. For end users, knowing that a yoga block contains 20% VA means it will hold up better to daily wear, feel less sticky, and avoid cracking under winter boots. Industry provides clear resin codes and identification numbers to sort, recycle, or select the right blend quickly.

Factories blend ethylene and vinyl acetate under high pressure in a reactor—imagine hundreds of atmospheres squeezing those molecules together while heat and a catalyst stir the pot. Pressures often climb above 2000 atmospheres, and temperatures frequently top 170°C. Technicians watch the ratio since small tweaks dramatically change the material’s flexibility and stickiness. Down the line, they pelletize the product, ready for melting and molding. EVA can get foamed with blowing agents, forming spongy sheets or shaped pieces for insulation or sports gear.

EVA’s backbone opens the door to chemical tweaks. You can cross-link it with peroxides, giving it more strength and heat resistance, turning foam blocks firm and springy. Some companies graft it with maleic anhydride, making EVA stick even better to metals or other plastics—a trick handy in automotive or wire coating. Sometimes, small amounts of coloring, UV stabilizers, and flame-retardants get mixed in to boost performance for outdoor use or electronic parts. I’ve watched lab techs test sample batches for unexpected reactions—humidity or stray chemicals can affect texture or strength if ratios are off.

People don’t always call it EVA. On a packaging label, you might see Ethylene-vinyl acetate copolymer, just E/VAC, or trade names like Elvax (DuPont) and Escorene (ExxonMobil). In shoe shops, EVA foam comes up more than copolymer numbers. Art supply stores often call it craft foam, while medical suppliers list it as a thermoplastic elastomer. Every sector has its own shorthand, which makes communication tricky for first-timers or buyers without a chemistry background.

EVA enjoys a reputation for safety in most consumer settings. Production plants maintain ventilation and monitor for volatile organic compounds released during compounding and foaming steps; dust control keeps fine particles from becoming respiratory hazards. In final products, EVA gives off little odor and no harmful plasticizers. Manufacturing standards draw from REACH in Europe and FDA regulations in the US to rule out dangerous heavy metals, lead, or phthalates. Workshops cutting EVA foam use goggles and dust masks—cuts with hot tools can give off small traces of acetic acid vapor, which stings lungs and eyes. These pieces of knowledge matter for teachers using EVA in school projects or for hobbyists crafting costumes at home.

EVA reaches into more corners of life than most people realize. Footwear makes up a massive slice—sneaker midsoles, flip-flops, sports pads all rely on its cushion. Medical fields use it in tubing, bags, and orthopedic padding because it stands up to disinfectants and doesn't trigger allergies like latex. Packaging teams trust EVA laminates for food, pharmaceuticals, or electronics, sealing freshness or preventing contamination. Cable sheathing and hot melt adhesives keep modern buildings connected and sealed against dust or pests. Greenhouses rely on EVA film for high light transmission and energy saving. In the solar panel world, EVA encapsulant sheets protect fragile photovoltaic cells, keeping water and debris at bay over decades. Artistic circles bend and layer colored EVA to make costumes, props, or sculptures.

Recent years push research toward tougher, greener, and smarter materials. Scientists search for ways to boost recycled content, decrease toxic additives, and improve performance under stress or sun. Labs explore bio-based alternatives, like using plant-sourced ethylene instead of fossil fuel feedstock. Research at the interface of nanotechnology and polymers adds nanoparticles or fibers to EVA for increased strength, heat deflection, or functional properties, such as conductivity or antimicrobial activity. Real progress comes out of partnerships between academic institutions and industry, where pilot projects get scaled up for real-world testing. These collaborations matter for everyday users because stronger, safer, or lower-carbon options will change product lifespan and environmental impact.

Toxicity studies on EVA and its breakdown products show low health risks at normal use levels. Medical device watchdogs and environmental agencies keep a close eye on potential leaching or release of vinyl acetate monomer, which has some links to health concerns in raw form—but after polymerization, those risks drop sharply. Waste handling raises more questions. Burning or improper disposal can form acetic acid, formaldehyde, or trace VOCs, which pose breathing hazards or contribute to smog in poorly ventilated areas. Consumer groups and regulators track recycling and end-of-life handling, pushing for collection programs or safe landfill protocols. Ongoing studies focus on microplastic behavior of EVA fragments in soil and water, especially as global plastic waste gets more attention.

Demand for versatile, affordable plastics isn’t slowing down, and EVA keeps finding new jobs. Markets for sports and athleisure, green tech, and packaging keep fuel in the tank for material innovation. Solar panel encapsulants make up a fast-growing segment as rooftop installations and grid-scale projects spread worldwide. Recycling remains a challenge: EVA’s cross-linked or foamed forms don’t melt back down as easily as simple plastics, spurring new research into chemical recycling or biodegradable analogs. Sustainability goals across industries encourage companies to experiment with plant-based versions and reduce single-use packaging out of fear of global pollution—fighting the same battles as every plastic producer. Smarter manufacturing, digital traceability, and tighter regulation stand to make EVA a cleaner, more responsible part of everyday life, if industry and researchers put their backing behind progressive solutions.

Ethylene Vinyl Acetate, usually called EVA, sneaks into places most people never notice. I remember opening up a pair of running shoes years ago, stripping away the outer layer to see what made them so springy. Right in the middle sat a foamy layer—lightweight, squishy, and just a little bouncy. That's EVA doing its job: keeping feet cushioned, steps soft, and knees grateful.

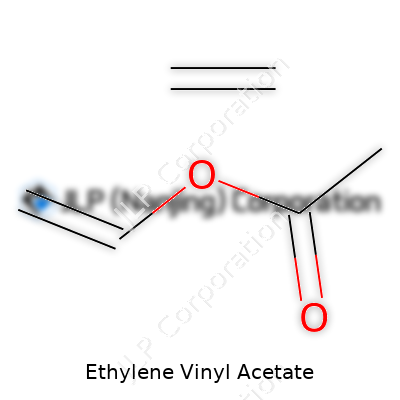

EVA comes from mixing ethylene and vinyl acetate, two chemicals that join together to create something strong yet flexible. Manufacturers love it because they can make it into sheets, foams, or even thin films. The stuff handles repeated pounding from feet without flattening out and shrugs off water if you drop your shoes in a puddle.

People see the lightweight midsoles in trainers, yoga mats’ gentle padding, or even the slick feel of flip-flops. These don’t just show up out of nowhere—EVA fills them, giving a little spring and protecting joints from shocks. Lots of kids’ playground mats rely on it too. You might not want to think about the number of tumbles that happen every day, but knowing that a soft, forgiving layer sits between a falling head and hard ground makes a real difference.

During school years, those cheap foam sheets for craft projects kept popping up in my backpack. They were soft, came in loud colors, and didn’t rip easily. That's EVA again. In the hands of children, it shapes into masks, flowers, or whatever their imagination cooks up. This material stands up to a lot of wrangling and doesn’t care much about spilled glue or markers.

EVA pulls weight far beyond sports and crafts. Open up any fresh electronics box and find that snug, custom-fitted padding—there's EVA, absorbing bumps during shipping. Solar panel makers use it too. They sandwich photovoltaic cells with it, knowing EVA sticks well and locks out moisture, dust, and air. Reliable, affordable, and resistant to sunlight, it keeps panels running for years.

Everywhere I travel, whether it’s a weekend camping trip or city hiking, I see its touch. Cooler linings, protective helmet padding, handlebar grips, even medical braces rely on EVA for their mix of comfort and performance. Unlike hard plastics that crack under pressure, or rubbers that rot and smell, EVA feels softer—and keeps that “new” feeling for a long time.

The flip side pops up in landfills. EVA doesn’t just disappear after we’re done with it; most types don’t break down quickly. That’s become a problem, especially in places overflowing with discarded shoes, broken yoga mats, or single-use packaging. While it offers plenty of benefits, waste piles up. Right now, some companies work on recycling programs that chew up old EVA, break it down, and reshape it for new uses. In some regions, small businesses collect worn-out flip-flops and send them back to factories for reprocessing.

Looking at today’s world, finding smarter ways to make and remake EVA products makes a lot of sense. Choosing durable goods, setting up return systems, and even developing bio-based versions could offer a way out of the landfill trap. For now, EVA keeps showing up in shoes, gear, and packaging, making life softer, safer, and brighter—sometimes whether we notice or not.

Take a walk through most homes, and you’ll probably find EVA somewhere. Kids’ foam puzzle mats, flexible shoe soles, packaging inserts, even yoga props—many of these soft, bendable items use ethylene-vinyl acetate, better known as EVA. Retail shelves label it as “BPA-free” or “non-toxic,” which reassures shoppers, especially parents. But it’s natural to wonder if a label tells the whole truth.

EVA combines ethylene and vinyl acetate, forming a soft plastic that feels a lot like rubber. Out of curiosity, I once sliced open a worn-out flip-flop made from EVA. Underneath the scuffed top layer, the foam looked spotless. The material resists crumbling and keeps its bounce, lasting through summer hikes and pool decks alike. Part of the appeal is that EVA doesn’t contain phthalates or heavy metals—common villains that regularly show up in headlines about toy recalls.

Laboratory studies back up the absence of these nasties. Most reputable manufacturers avoid adding chemicals that pose cancer risks. Plus, EVA is free from PVC and BPA, notorious for hormone disruption. The FDA even gives a nod to EVA for some types of food packaging, though never for products exposed to high heat.

Still, not all stamping of “non-toxic” says enough. Choices in production—fillers, dyes, adhesives—could introduce new risks. You’ll find EVA mats with that strong new-plastic smell, likely from leftover solvents or chemical additives. This scent fades over time, but if you’ve noticed headaches or sore throats after opening a new yoga mat, you’re not alone. Some folks report irritated skin after contact, especially when sweating.

Scientific research shows pure EVA is considered safe for day-to-day use at room temperature. Problems tend to show up with high-heat exposure, like when EVA gets burnt, melted, or used in microwaves. This produces acetic acid and other unwanted byproducts. That’s why you’ll see warnings to keep craft foam—often made of EVA—away from kids’ mouths or heat guns.

Trying to find the safest products? I stick with brands willing to show third-party safety certification, such as Oeko-Tex or UL. A company that reveals what goes into its EVA foam, skips strong scents, and offers clear information online wins my trust. I avoid bargain-bin mats covered in glitter or loaded with designs that flake off within weeks. These often skimp on quality controls, which could mean shortcuts in the formula.

Tossing damaged EVA gear helps, too. A torn foam mat, flooded beach float, or worn-down flip-flops can start to crumble, which means microplastics end up in drains, playgrounds, or creeks down the street. No material comes risk-free, but keeping EVA products in good shape and following label guidance—especially about heat or age limits—offers a practical way to cut down on worries at home.

Community pressure for safer materials drives improvement. Schools and gyms make bulk orders for EVA floor tiles, so asking suppliers for proof of safety really makes a difference. Meanwhile, as eco-friendly options grow, some brands offer EVA blended with natural fillers or reclaimed foam. Supporting these efforts shifts the market, making it easier for everyone to pick non-toxic, durable products—without having to dig through pages of fine print before buying a simple pair of sandals or a mat for playtime.

If you've ever picked up a pair of running shoes, a flip-flop, or even a yoga mat, chances are you've had a brush with EVA—short for ethylene-vinyl acetate. On paper, it sounds like a chemical experiment, but in daily life, this material pops up everywhere. EVA welds together the best of both worlds from its two ingredients. It blends the toughness of plastic with a bounce and flexibility you’d usually expect from rubber.

Step on a pair of EVA-soled sneakers, and you’ll feel a spring underfoot. That’s where its shock absorption comes into play. The foam structure acts almost like millions of tiny air pockets, softening every step. Nobody enjoys aching feet after a stroll or a run, and EVA has quietly changed that reality. You’ll feel it cushioning playground safety mats or lining the insides of sports helmets, too.

People bend, stretch, and flex. Footwear and sports gear made with EVA need to keep up. I’ve seen it take a beating in skate shoes that get bent hundreds of times before lunch break or yoga blocks that squash and rebound every session. It bends and then returns to shape, time after time. That “memory”—the ability to keep bouncing back—explains its huge popularity with designers chasing softer, friendlier materials for all ages.

Damp days or sudden spills don’t leave EVA out in the cold. Compared to plain rubber, EVA puts up a stronger fight against water and the mold or bacteria that try to hitch a ride. I’ve left flip-flops and kids’ pool noodles at the edge of a puddle more times than I can count, and they haven’t changed shape or grown slippery. They dry fast and keep their grip better than most alternatives, which makes them a go-to for beach and poolside gear.

EVA’s safety record makes it a trusted guest in products for infants, athletes, and pretty much everyone between. It rarely sparks allergic reactions and holds up well against a lot of chemicals. Still, an growing number of people feel uneasy about plastics and what happens after we toss them. EVA doesn’t melt down easily in most recycling bins, which creates a tough challenge—its world-changing comfort comes with a hidden cost. Some shoe brands now experiment with plant-based versions and closed-loop recycling to reduce waste, but big changes take time.

EVA gets soft and comfy by design, but that same softness can wear down, especially in shoes that hit the pavement hard. Shoe manufacturers face a trade-off: more bounce now can mean faster breakdown later. Upgrading formulas and mixing in tough fibers help shoes last longer, but nothing beats giving worn-out products a second life. Donating for reuse, sending back to brands running recycling programs, or supporting emerging biodegradable EVAs all nudge things in the right direction.

Every time EVA ends up in the gear people use—shoes, toys, athletic padding—it quietly improves comfort and resilience without breaking the bank. For families, athletes, and makers, EVA’s combination of lightness, shock absorbing power, and durability continues to shape everyday life. For all its perks, figuring out the end-of-life problem could define the next chapter. The magic lies not just in what EVA does today, but how we handle its impact tomorrow.

Walk into any toy store, cable factory, or sports equipment shop, and you’ll find EVA, PVC, and PE hiding in plain sight. These plastics share everyday space, but each one brings something different to the table. Years of working with packaging and sports goods taught me to notice which one ends up where, and for good reason.

EVA, or ethylene-vinyl acetate, brings a signature softness and bounce. People love it for flip-flops, pads, or shock-absorbing foam. I’ve spent days cutting EVA sheets for kids’ craft projects, and not once did anyone complain about the smell. That’s a quiet upside — EVA doesn’t carry the chemical odor associated with vinyl. It’s lightweight, flexible, and not brittle. Try bending a sheet of EVA, and you’ll see it flex without snapping.

Kids’ play mats often use EVA, partly because it’s not as harsh as hard plastic and stands up to coloring, drops, and gnawing toddlers. People using EVA in watersports also mention its grip. After all, no one likes slipping on a paddleboard or boat deck.

PVC — polyvinyl chloride — shows up wherever toughness and clarity matter. Think clear pipes, cables, or even imitation leather. PVC’s biggest strength lies in how sturdy and durable it feels, especially for protection. But it’s got one noticeable drawback: people have long questioned how safe it is with extended contact, especially around children or food. Concerns about additives like phthalates and chlorine come up every few years.

I’ve worked with cable sleeving and often had to air out the PVC smell. The chemicals make PVC fire-resistant, which matters for building and safety, but those same additives can leach out under the wrong conditions. For garden hoses or kids’ raincoats, that sometimes means reshuffling the material pick altogether.

You can find polyethylene (PE) just about everywhere: plastic bags, bottles, milk jugs, water pipes. It’s cheap, solid, and doesn’t raise many eyebrows in terms of safety. Ever wondered why milk comes in those slightly flexible clear bottles? PE avoids strange tastes or smells.

PE doesn’t match EVA’s feel for cushioning, and it can get slippery. Holding a PE bag full of groceries, you might feel your fingers slip if your grip isn’t tight. At the same time, PE shrugs off many chemicals and even extreme cold. That’s helpful for food storage and transport. PE pipes run through many homes because they don’t corrode, don’t break easily, and the cost beats out metals hands down.

Selection rarely happens by accident. If contact with skin or food matters, EVA and PE handily edge out PVC. For outdoor uses or construction, durability, cost, and safety standards push companies toward PE or occasionally PVC, provided regulations are met. EVA lands almost naturally in comfort-oriented products.

Environmental questions linger across all plastics. EVA resists biodegradation, PVC can cause toxic waste when burned, and PE taunts recycling systems with its stubbornness. None look perfect, but picking the right one cuts down risk and waste at every stage. For designers and manufacturers with an eye on the future, the safest, most practical choice often wins by default. Factoring in health, flexibility, and longevity means EVA, PVC, and PE each earn their keep, provided they end up in the right place.

It's easy to forget just how many places EVA, or ethylene-vinyl acetate, pops up in modern life. That squishy, flexible foam makes running shoes bounce, keeps flip-flops comfy, even pads packaging and toys. Now, more people stop to wonder what happens once those sneakers wear out, or packing foam lands in the bin. Does all that EVA just add to landfill hills? The big question: can EVA actually get recycled?

I’ve watched a heap of EVA go to waste, from overstuffed gym shoes to blocks tossed out after moving house. Most folks probably feel a twinge of guilt sending foam to landfill, even if they can’t think of alternatives. It’s frustrating, too, because the material feels reusable. But, there’s a snag. Recycling this "soft plastic" isn’t as straightforward as the old PET bottle or cardboard box. Standard recycling trucks usually don’t grab EVA, so it escapes the usual curbside pickup. That’s not laziness—just a system that rarely bothers with trickier plastics. Some recycling centers just see it as "unlabeled plastic," and shrug it off.

What's the holdup? Breaking down EVA takes effort. It doesn’t melt like many other plastics, and the mix of vinyl and ethylene takes specific equipment to handle. City recycling plants don’t want to risk gumming up expensive machines for a foam they barely ever see. Smaller pieces also get lost or cause clogs, so the bins just fill with more cardboard and bottles. That's what I've heard from talking to people at local drop-offs—they just don't have the machinery or the time.

Even if someone collects a pile of EVA at home, recycling shops usually won't accept a small load. Big companies, though, sometimes collect offcuts from factories and send them to specialized recyclers. Here, the foam gets shredded and heated, then squished back into new roles, like floor mats or playground tiles. So, large volumes see new life, but small everyday items usually escape this process.

Listen, no one wants a mountain of used foam haunting future generations. Landfill space doesn’t stretch forever, and EVA doesn’t break down quickly. PVC often gets a bad rap for pollution risk, but EVA resists breaking down for just as long—sometimes hundreds of years. Reports warn about plastics leaching chemicals, and while EVA is safer than some, its sheer volume adds up.

People have tried bringing attention to the problem. Shoe brands explored “take-back” programs, collecting old sneakers to recycle their foam, but these projects often stall. Collecting and shipping foam take money, and without mass participation, costs don’t drop. Still, I know schools and community centers happy to accept gym mats made from recycled EVA. If local governments and companies pulled together, more coordinated collection programs could get off the ground.

Other countries have experimented with melting and remolding EVA at dedicated plants. These systems won’t work everywhere, but seeing creativity from other places offers hope. Designers can play a part too, picking materials that either use recycled EVA or skip it where it isn’t necessary.

No one person can shift the whole supply chain, and families can’t lug heaps of EVA to a plant thousands of miles away. But bringing the problem into daylight pushes companies to act, and consumers to ask tougher questions before buying that next pair of sports shoes. If people pause and push for better options, chances grow for a foam future with less waste, more recycling, and fewer landfill-bound sneakers.

| Names | |

| Preferred IUPAC name | poly(ethene-co-ethyl ethenate) |

| Other names |

EVA Ethene-vinyl acetate copolymer Poly(ethylene-co-vinyl acetate) Vinyl acetate ethylene copolymer |

| Pronunciation | /ˈɛθɪˌliːn ˈvaɪ.nəl əˈsiː.teɪt/ |

| Identifiers | |

| CAS Number | 24937-78-8 |

| Beilstein Reference | 1761005 |

| ChEBI | CHEBI:53251 |

| ChEMBL | CHEMBL1279659 |

| ChemSpider | 24319 |

| DrugBank | DB09534 |

| ECHA InfoCard | 03f2a6e2-9b35-47b5-af7c-9cb9870ee321 |

| EC Number | 249-545-9 |

| Gmelin Reference | 8057 |

| KEGG | C22137 |

| MeSH | D004995 |

| PubChem CID | 6098048 |

| RTECS number | KV9400000 |

| UNII | KM2Q0WOM75 |

| UN number | UN3082 |

| CompTox Dashboard (EPA) | DTXSID6020084 |

| Properties | |

| Chemical formula | (C2H4)x(C4H6O2)y |

| Molar mass | 86.09 g/mol |

| Appearance | White to yellowish solid or powder |

| Odor | Faint, waxy odor |

| Density | 0.92 g/cm3 |

| Solubility in water | Insoluble |

| log P | 3.3 |

| Vapor pressure | ~1 mmHg @ 20°C |

| Acidity (pKa) | > 25 |

| Basicity (pKb) | pKb: 15.1 |

| Magnetic susceptibility (χ) | −7.6×10⁻⁶ |

| Refractive index (nD) | 1.494 |

| Viscosity | 250 cP |

| Dipole moment | 1.78 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 361.3 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -481.14 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2970 kJ/mol |

| Hazards | |

| Main hazards | May cause irritation to eyes, skin, and respiratory tract |

| GHS labelling | GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | Hazard statements: Not classified as a hazardous substance or mixture according to the Globally Harmonized System (GHS). |

| Precautionary statements | P210, P261, P280, P305+P351+P338, P337+P313, P501 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | Flash point: > 230 °C |

| Autoignition temperature | 350 °C |

| Lethal dose or concentration | LD50 (oral, rat): > 2000 mg/kg |

| LD50 (median dose) | LD50 (oral-rat) > 2000 mg/kg |

| NIOSH | **KVJ2** |

| PEL (Permissible) | 50 ppm |

| REL (Recommended) | 10 ppm |

| Related compounds | |

| Related compounds |

Polyethylene Polyvinyl acetate Polyvinyl alcohol Ethylene-propylene rubber Polyolefin elastomers |