Digging into the story of acetic acid takes you all the way back to ancient civilizations. People first stumbled on its sour punch when wine or other alcoholic brews started turning bad, leading to what we now call vinegar. Alchemists tossed around names and methods, but this simple acid kept showing up, whether they tried to distill spirits or pickle food. In the late 18th century, the chemist Carl Wilhelm Scheele managed to isolate acetic acid in a purer form. Chemical industries in the 19th and 20th centuries scaled up the production, no longer depending on spoiled wine, switching instead to cracking wood or fermenting sugars. Innovation arrived with the catalytic oxidation of acetaldehyde, and today’s plants often rely on methanol carbonylation, offering much higher efficiencies. This shift from artisanal vinegar pots to big reactors changed how people think about chemical feedstocks, linking something as familiar as table vinegar to global markets and giant industrial chains.

Acetic acid shows up in glass bottles and recoil drums, sometimes diluted, sometimes highly concentrated. In grocery stores, a bottle labeled “vinegar” rarely contains more than 5-8% acetic acid, but the industrial standard rests at 99-100%, popping open a pungent, eye-watering aroma on the first whiff. Manufacturers offer grades for food, pharma, or technical use. Clear labeling tells buyers the purity, matches to standards like FCC, BP, or USP. Production doesn’t just fill supermarket shelves; the acid forms the backbone for vinyl acetate monomer, acetic anhydride, and hundreds of derivatives, all of which stir through everything from adhesives to plastics.

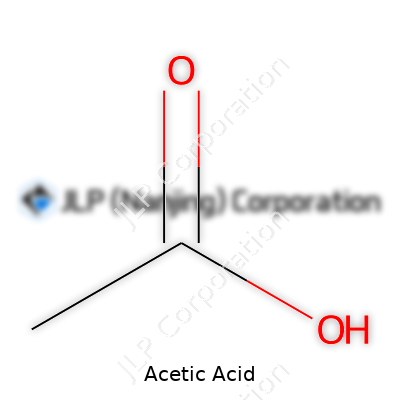

Acetic acid, or ethanoic acid if you're looking for the textbook name, is a clear, colorless liquid at room temperature but can freeze up in a chilly warehouse. It solidifies around 16.6°C, giving it the nickname “glacial” when pure—a term rooted more in frosty warehouses than glaciers. It has a biting, sharp smell familiar to anyone who’s opened a hot vinegar bottle, and it mixes well with water thanks to its polar nature and hydrogen bonds. The acid itself, CH3COOH, stands out for being both corrosive and flammable—certainly a step above vinegar in potency. In water, it doesn’t give all its protons away, so even though it's called a “weak acid,” it can burn skin and attack metals, turning them into their respective acetates with surprising eagerness.

Buyers and handlers lean on specifications like purity, moisture content, trace metals, and any residual aldehydes. Food and pharmaceutical industries demand purity above 99%, with strictly controlled heavy metal traces. Labels have to warn about corrosivity, keep flammability in mind, and show batch and expiry data. Barcode systems and QR codes have helped improve traceability in the supply chain, making recall or audits less of a nightmare. A careful look at the Safety Data Sheet (SDS) pays off, especially since concentrated acid can cause burns or dangerous fumes.

Early batches of acetic acid came from biological fermentation, relying on acetic acid bacteria to chew through ethanol and yield weak vinegar. Chemical engineers eventually steered toward synthetic methods. Pyrolysis of wood gave way to acetaldehyde oxidation, which later lost ground to methanol carbonylation on a rhodium or iridium catalyst. These reactions keep energy use and feedstock costs in mind, important for global suppliers hoping to beat rivals on price. Green chemistry efforts now try to cut fossil input and capture waste heat, which nods to environmental pressure more than sentimentality for the old vinegar vats.

Acetic acid is more than just a cleaning agent or flavoring. It handles versatile reactions—esterification with alcohols pumps out all sorts of useful esters. Treating it with anhydrides or chlorides generates aggressive acetylating agents, turning out cellulose acetate for film, or aspirin in pharma plants. The acid also serves as a solvent for reactions needing mildly acidic media. Sometimes, it’s just a partner in the background, tweaking pH or buffering chemical cocktails that can’t stand strong bases or acids. On the more academic side, researchers dig into how it interacts with enzymes, metal ions, or catalysts, figuring out ways to control industrial chemistry more precisely.

Searching through inventories, acetic acid might hide behind names like Ethanoic acid, Glacial acetic acid, E260 (on food labels), or even Vinegar acid. In the world of trade chemicals, CAS No. 64-19-7 points to only one thing. Some regional vernacular sticks to “essigsaure” or “acide acétique,” echoing its culinary start. Not all products are food-safe, so a good eye for synonyms helps avoid dosing a salad with industrial stock.

Handling pure acetic acid sets off alarms in any lab or factory. Splash goggles, gloves, good ventilation, and acid-resistant containers are daily gear. The acid eats through some metals, boils into irritating fumes, and inflames if mistreated near open flames. Inhalation, skin, or eye contact cause injuries—emergency showers or eyewash stations need to stay nearby. Many workplaces also set up spill kits and “buddy” systems for anyone refilling big drums or transfer tanks. The acid doesn’t travel alone; empty drums can still hold hazardous residue. Strict protocols on storage temperature and segregation from bases, oxidizers, or reactive metals cut down the odds of a nasty event.

Industrial zones use acetic acid for more than pickling or salad dressing—it plays a key part in manufacturing acetate fibers for textiles, as a solvent for ink and dye production, and in the synthesis of various plastics such as polyethylene terephthalate (PET). Laboratories depend on it as a reagent or pH control agent. The food industry leans on milder concentrations to flavor and preserve sauces or pickles. Water treatment plants sometimes use the acid in scale prevention or nutrient removal. Farmers rely on acetic acid in some herbicide blends, especially for organic certifications that refuse synthetic weedkillers. It even plays a part in cosmetic formulations and movie film bases. Its broad reach means one product pops up in cleaning closets, hospital supply rooms, manufacturing lines, and biotech startups.

Sustainability concerns drive much of today’s research work. The search for renewable feedstocks, less energy-intensive reactions, and value-added byproducts steer both basic and applied labs. Projects examine electrochemical conversion of CO2 and biomass pathways as greener alternatives to petroleum-based routes. Chemists and process engineers hustle to tweak catalysts, chasing higher yields and lower environmental footprints. Analytical chemists explore detection limits for acetic acid in process streams, wastewater, or final products—since even small impurities harm sensitive manufacturing. On the biotech side, research into acetic acid bacteria and optimized fermentation paves the way for bio-based supply.

Scientists have measured both acute and chronic effects of acetic acid exposure. For workers, concentrated vapor in the air causes immediate irritation of eyes, skin, and the respiratory system; NIOSH sets a recommended exposure limit (REL) at 10 ppm over 8 hours. Large spills or direct contact trigger chemical burns or more severe injuries. Drinking strong solutions risks internal burns and, at high doses, organ damage. Regulatory bodies track its movement through soil and water, checking for environmental impact. Toxicologists use animal models and in vitro testing to study long-term exposure, especially for populations in close proximity to large production sites. Proper labeling, training, and workplace air monitoring keep exposure well below dangerous levels; most problems come from accidents or neglect, not daily use under good controls.

The story of acetic acid is far from finished. As the chemical industry faces down calls for net-zero production and circular economy cycles, more companies are investing in green methanol, captured CO2, or fermentation-based acetic acid. Tech firms and industrial giants alike aim to squeeze more from less—higher efficiency, cleaner emissions, and less wastewater. Regulatory shifts and consumer demand for safer food preservatives, less plastic waste, and renewable sourcing keep research teams on their toes. It also feels likely that new applications—perhaps in battery electrolytes, advanced materials, or precision fermentation—could give acetic acid a starring role beyond what anyone imagined in those ancient wine casks. While predictions feel risky, anyone paying attention to the worlds of synthetic biology, renewable energy, and food tech can bet on acetic acid sticking around, always on the edge of something new.

Acetic acid always pops up in the kitchen, disguised under its everyday nickname—vinegar. A bottle tucked in the pantry offers a sharp kick to salad dressings or does a decent job taking out limescale on the faucet. It’s easy to see it as just a household helper, but this small molecule finishes a long to-do list far outside the kitchen.

Any time you see a shiny cucumber or crunchy carrot on a store shelf, preservation sits at the center of that process. Pickling uses acetic acid as a food-safe way to ward off rot and spoilage. In one bite of pickled herring or a juicy pickle spear, you’re tasting more than flavor. You’re tasting safety and shelf life—two things that defenders of food security keep a sharp eye on.

Switch over to food processing, and you’ll spot acetic acid in places you wouldn’t expect. Factories use it to keep certain products free of bacteria and mold. They know a few drops in the right spot can mean longer storage and fewer recalls. Food scientists pay attention to how acetic acid keeps cheese, sauces, and condiments stable through shipping and months in the fridge.

Grandparents swear by vinegar and water for windows, but there’s more to the story. Acetic acid acts as a solvent, cutting through calcium deposits and tough grime that other cleaners barely touch. Fewer specialty products crowd shelves if you lean on this classic remedy for natural, cheap cleaning—an answer that keeps harsh chemicals out of drains and off skin, especially in homes with kids or pets.

Step away from the grocery store and labs turn acetic acid into something much bigger. Manufacturing plants crank out acetate fibers for clothing, making textiles less starchy and stiff. Construction workers don’t often realize that adhesives and paints use ingredients built on acetic acid backbones, making everything from hardwood floors to ship hulls last longer.

Painters trust a fresh can of latex paint not to clump or separate, and chemical engineers know acetic acid helps keep those formulas steady. Without it, whole industries would pay more to fight waste, clogs, and stuck-together materials.

Hospitals and clinics rely on acetic acid as more than a sterilizing wipe. Dilute it and you have a gentle acid bath for wound care, with enough kick to kill germs while keeping living tissue safe. Some gynecologists put a dab on a cervix during screening, turning suspicious cells white for cancer checks. Most folks don’t imagine that a substance from a salad dressing recipe could help doctors spot disease early and lower infection risks.

No chemical comes without downsides. Around concentrated acetic acid, I’ve always handled it with gloves and good ventilation. Splashes sting, and strong fumes make the nose burn. Factories with lax safety gear see hospital trips from careless spills. Limiting exposure and making sure only the trained handle strong stock should always rank above convenience.

Pushing alternatives where possible, such as biodegradable cleaners and green preservatives, would also help lower the footprint acetic acid leaves. Science and experience can nudge us toward smarter, safer uses—turning an old staple into something a little less risky and a whole lot more helpful.

Growing up, I always thought of acetic acid as the ingredient that makes vinegar smell sharp and taste sour. The truth is, acetic acid exists in much higher concentrations in chemical labs and factories than in the bottle my grandmother poured into her salad. At household levels, it’s just vinegar. Industrial or laboratory-grade acetic acid, though, can pack a punch.

Glacial acetic acid looks almost like water and can fool you into thinking it’s pretty harmless. That assumption can lead to trouble. Concentrated acetic acid can burn your skin, damage your eyes, and produce strong fumes that irritate lungs and throat. I remember a chemistry lab where dropping a bit of glacial acetic acid onto my gloves made them feel hot; the warning was clear. Gloves, goggles, and a fume hood turned out to be non-negotiable allies.

One reason folks get confused about acetic acid: we think of it as “just vinegar.” It’s easy to forget that the stuff found in cleaning aisles or science labs has a much higher strength. This lack of distinction can open the door to carelessness. Most accidents I’ve seen or read about involve people skipping basic protection—a splash on an unprotected hand or, worse, an eye. According to the National Institute for Occupational Safety and Health, skin contact with concentrated acetic acid can cause blistering and long-term injury.

Beyond burns, there’s also the risk from inhaling fumes. Acetic acid vapor in high concentrations can make people cough and struggle for breath. Over time, repeated exposure may cause lung problems. Many don’t realize that containers don’t need to be open for fumes to escape. I’ve walked into storerooms where the air stings, just because a lid wasn’t tight enough. Simple mistakes pile up when you think you’re just dealing with “vinegar.”

Not everyone needs a full hazmat suit to work with acetic acid, but basic respect for the substance makes a world of difference. I always reach for nitrile gloves and goggles—never once considered skipping those steps after seeing what happens without them. These aren’t just recommendations tucked away in safety manuals; they actually work.

Ventilation makes a big difference, too. Fume hoods in labs aren’t luxury items, they’re there for a reason. If you’re handling even small bottles, crack a window or use an exhaust fan. Storage matters just as much. Keeping acids in well-marked, tightly sealed containers stops most issues before they start.

It helps to call acetic acid what it is, not just vinegar. Training and clear language beat assumptions every time. Employers who run regular safety briefings and put up clear signs reduce accidents. Home tinkerers—anyone making pickles or homemade cleaners, for example—should stick to white vinegar from the store, and avoid “concentrated acetic acid” kits unless they have proper training.

To me, safety comes down to treating every strong chemical as if its risks are real. Acetic acid deserves that practical respect, whether in a high school classroom or a chemical plant. The right habits mean this chemical stays just another helpful tool—and not a source of regretful stories.

Acetic acid might sound tame compared to some chemicals. It pops up in kitchens as vinegar, but the pure stuff acts nothing like the bottle most people sprinkle over french fries. At high concentrations, it can burn skin, eat through metal, and fill the air with nasty fumes. In warehouses and factories, a slip in judgment over storage puts not only the expensive drum at risk but also the people nearby.

Open a bottle of acetic acid, and the strong, sharp smell makes it clear—this isn't apple cider vinegar. Storing it starts with strong, air-tight containers built from materials it doesn’t break down. Most folks working with it learn early that glass, certain plastics (like polyethylene), and stainless steel tend to handle its strength. Put acetic acid in a metal that can’t cope, and leaks show up before long.

If you step into a chemical storage room, signs reading “flammable” and “corrosive” on the acetic acid drum aren’t just warnings for the paperwork. The liquid catches fire if it finds a stray spark, and its vapors love to travel. I remember a colleague telling me about a storage area where poor ventilation led to a faint vinegary sting in the air—a sign something wasn’t right. Ventilation and cool temperatures stop fumes from building up, making it safer for anyone walking by.

Carelessness costs. Spill some concentrated acetic acid on your hands, and you’ll feel the burn for days. Nearby drums filled with strong acids or oxidizers? Mix-ups during storage can spark dangerous reactions. There’s a reason labels get checked and double-checked, and why drums stand well apart from reactive chemicals.

I’ve seen more than one warehouse where a lack of clear labeling led to long nights sorting out which drum held what. One oversight led to a near miss—acetic acid close to chlorine bleach. That pairing could have gassed everyone out of the building. The lesson sticks: don’t take shortcuts with storage maps and color-coded tags on barrels.

People who handle acetic acid learn to keep goggles and gloves close by, and showers within sprinting distance. Training isn’t about checking a box, but about making sure everyone’s ready when something splashes or tips. In the places I’ve worked, the best supervisors never got tired of quick safety reminders. It’s about protecting everyone who has to move, measure, or transport this strong-smelling liquid.

Regulations back up these steps. The Occupational Safety and Health Administration (OSHA) lays out the rules: corrosive materials like acetic acid must get separate shelves, proper seals, good ventilation, and the right personal gear. Some places use spill kits and neutralizers for quick clean-up. These aren’t suggestions—they’re how people avoid hospital trips.

Companies pay less on cleanup and insurance when people store acetic acid right. Newer storage systems have alarms for leaks and temperature spikes, so problems get fixed before they spread. Couple simple safety basics—like separating incompatible chemicals and keeping aisles clear—with better technology, and storage becomes one less headache in the workday.

It takes stubborn attention to detail and some upfront investment to store acetic acid safely. But for anyone who’s seen what goes wrong when someone ignores the rules, it’s not a tough choice. Good storage is the difference between getting work done and everything grinding to a halt over one overlooked hazard.

Some years ago, I bought a jug of vinegar for pickling vegetables. I didn’t check the label, assuming all vinegar was the same. The recipe failed—mushy cucumbers, not a crisp one in sight. It turned out my “vinegar” was just 4% acetic acid, weaker than the usual 5% used in pickling. Anyone who’s spent time in a kitchen or lab runs into moments like these, where a tiny difference in concentration makes all the difference.

If you look at acetic acid sold at hardware stores, you’ll notice a lot of numbers on the packaging. Supermarkets usually stick to 4%-7% in standard vinegar, good enough for salads but not cleaning limescale or preserving food. Tech shops and chemical suppliers might sell 30%, even 99% “glacial” acetic acid—strong enough to demand gloves and goggles and to attack skin or stainless steel. The jump from kitchen vinegar to pure chemical isn’t just about strength; the risks climb fast. Breathing in concentrated vapors stings the eyes and nose. So, the label isn’t just a bureaucratic tag—it's your first line of defense.

Some people try to stretch their cleaning vinegar by watering it down or boost cheap vinegar by boiling it away. This kind of guesswork can land you in trouble. Diluted vinegar can’t clean mildew or disinfect food-safe surfaces. Extra-strong acetic acid, on the other hand, corrodes counters and irritates skin. The safe and right concentration depends on the job. Trusting the label or doing a simple titration if uncertain beats guessing every time.

Factories use big vats of acetic acid with strictly controlled strengths. Textile dyeing, food preservation, and even pharmaceuticals all rely on careful mixtures. If the batch runs too strong, the chemical reactions misfire or products turn out unstable. Too weak, and the results lack oomph, putting business at risk and workers under pressure to troubleshoot. Employees get trained to check and double-check acetic acid before mixing. A mistake doesn’t just waste materials—it can halt production or start a chain of costly recalls.

I learned to keep a cheap pH strip kit tucked in my pantry, and I recommend others try it too, especially for canning or cleaning. A simple strip takes seconds and tells you whether you’re working with a safe, effective acid or glorified flavored water. In group settings, like community kitchens or school labs, posting a chart of common concentrations can help newcomers avoid mistakes. In industry, barcode systems and digital records make traceability tighter, but the basic principle holds: If you don’t know the concentration, don’t start the job.

Paying attention to that percentage isn’t about being fussy—it’s about watching each step so the next step works out right, whether you’re pickling vegetables, degreasing an engine, or producing medicine. Acetic acid only does its job if you know its strength and match it to your job’s real needs.

Anyone who's worked in a lab or industrial plant has faced spills. Acetic acid might sound mild, especially since it shows up in vinegar, but in higher concentrations, it's tough stuff. That sharp smell and burning feeling on skin are warning signs. Small mistakes can mean costly downtime, serious injuries, or even long-term damage to equipment. Forgetting the impact of a slip—both on health and on operations—can haunt a workplace for months.

Response speed matters most. People don’t pause to read the chemical safety data sheet in a panic. Practical training wins over theory every time. I’ve seen too many spilled acids wiped with whatever’s nearest—even cheap paper towels—because proper supplies hid under piles or behind jammed doors. Spill kits need to stay stocked where real work happens, not locked in some distant storeroom.

Acetic acid eats through certain plastics and even corrodes metals, so sorbents and tools built for caustics keep people safer. Neutralizing agents for acids, such as sodium bicarbonate, handle the job but can foam up fast. Dumping massive amounts leads to splattering and slippery messes. Controlled application works better—goggles and gloves always come out before touching anything. Even a minute of carelessness leaves nasty burns.

Smothering a spill doesn't fix leftover fumes clinging to a room. Under the harsh hum of lab lights, air quality slips below safe levels in no time. Adequate ventilation saves lungs more than fancy air monitoring equipment. Propping open a window, switching on exhaust fans, and keeping people out make all the difference.

The job doesn’t end at a clean-looking floor. Wipes go straight into clearly labeled hazardous waste bags, sealed, and sent for proper disposal. Don’t mix these with regular trash—mistakes can put janitors or waste handlers at risk. It’s not worth skipping a step to shave time off the clean-up.

You can tell if a team drills for spills or just checks off boxes on a form. Rushed orientations create accidents down the line. Regular hands-on practice, like pretending to mop up a puddle of water and reviewing what works (or what’s missing), gives everyone more confidence when the real thing hits. That kind of readiness protected my former lab after a bottle dropped and burst. No panic, no chaos—just calm, practiced response.

Technology can help too. Apps now track chemical stocks and can even send out instant alerts about nearby hazards. A few taps bring up step-by-step guides with photos, avoiding the trap of forgetting crucial details in stressful moments. Even so, nothing rivals experience handed down by folks who've lived through incidents and stick around to tell the tale.

Most spills sneak up because someone pushes bottles to the back of a shelf, skips checking bottle seals, or stores more than needed. Workers who voice concerns and set up easy-to-follow labels for containers catch problems before they explode into emergencies.

Building a culture where people never feel talked down to for asking about safety brings more results than rules on paper. My habit of double-checking supplies and neat storage came from listening to veterans in the field—not from manuals. Acetic acid isn’t just another item on a chemical inventory. It demands respect, clear knowledge, good gear, and real camaraderie. That builds workplaces that bounce back from mistakes, not just survive them.

| Names | |

| Preferred IUPAC name | ethanoic acid |

| Other names |

Ethanoic Acid Glacial Acetic Acid Vinegar Acid Methanecarboxylic Acid |

| Pronunciation | /əˈsiːtɪk ˈæsɪd/ |

| Identifiers | |

| CAS Number | 64-19-7 |

| 3D model (JSmol) | `3D model (JSmol)` string for **Acetic Acid**: ``` CC(=O)O ``` |

| Beilstein Reference | Beilstein Reference: 1718730 |

| ChEBI | CHEBI:15366 |

| ChEMBL | CHEMBL153 |

| ChemSpider | 175 |

| DrugBank | DB03166 |

| ECHA InfoCard | 03b4ecf4-1ab4-41d9-bc65-0c4ac6be91f4 |

| EC Number | 200-580-7 |

| Gmelin Reference | 162 |

| KEGG | C00033 |

| MeSH | D001047 |

| PubChem CID | 176 |

| RTECS number | AF1225000 |

| UNII | Q369O8926L |

| UN number | 2789 |

| Properties | |

| Chemical formula | CH3COOH |

| Molar mass | 60.052 g/mol |

| Appearance | Clear, colorless liquid with a pungent, vinegar-like odor |

| Odor | Pungent, vinegar-like |

| Density | DENSITY: 1.049 g/cm³ |

| Solubility in water | Miscible |

| log P | -0.17 |

| Vapor pressure | 1.5 kPa (at 20 °C) |

| Acidity (pKa) | 4.76 |

| Basicity (pKb) | 14.76 |

| Magnetic susceptibility (χ) | -5.8×10⁻⁶ |

| Refractive index (nD) | 1.371 |

| Viscosity | 1.22 mPa·s |

| Dipole moment | 1.74 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 159.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −484.5 kJ·mol⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -875.8 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | S02AA10 |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS02,GHS05,GHS07 |

| Signal word | Danger |

| Hazard statements | H226, H314, H318 |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P260, P264, P280, P301+P330+P331, P303+P361+P353, P304+P340, P305+P351+P338, P310, P311, P321, P363, P370+P378, P403+P233, P405, P501 |

| NFPA 704 (fire diamond) | 2-3-2-Acidity |

| Flash point | 39 °C |

| Autoignition temperature | 427 °C (801 °F; 700 K) |

| Explosive limits | 4% (LEL), 16% (UEL) |

| Lethal dose or concentration | LD50 (oral, rat): 3,310 mg/kg |

| LD50 (median dose) | LD50 (median dose): 3310 mg/kg (rat, oral) |

| NIOSH | KW7875000 |

| PEL (Permissible) | 10 ppm |

| REL (Recommended) | 10 ppm |

| IDLH (Immediate danger) | 50 ppm |

| Related compounds | |

| Related compounds |

Acetic anhydride Acetyl chloride Acetate Formic acid Propionic acid |